-40%

EB683513ME; GREASE PUMP REPLACEMENT INDUSTRIAL; 50:1 Ratio; HIGH PRESSURE;

$ 158.39

- Description

- Size Guide

Description

LT83513MEDescription: Replacement High Pressure 50:1 Ratio Grease Pump for Industrial Containers, Pails, Drums & Tanks.

1: Includes 50:1 Ratio; Double Acting High Pressure Pump (LT83513ME) delivers uniform pressure on the up and down stroke.

2: Rapid Disconnect Coupler(815ME) & Air Nipple 1/8"(M)

3: Muffler(LT2601ME)

4: Pump Specifications: Pump Tube Length 18-7/8"(47.9 CM) & Diameter 1.0"(2.54CM); made for Industrial Pails, Containers and Drums; Air Motor height: 11.0"(27.84CM); Overall height of Unit: 29-7/8"(75.8CM);

5: These high pressure Grease Pumps incorporate a 20 cu. in. air motor design.

6: Output: 80 cu in/minute (45 oz) of Grease at 100PSI NLGI#2 at 70 Degrees ambient temperature (.35 cu in/cycle)

7: Air Inlet 1/8” NPT (f); Lube Outlet: ¼” NPT (f)

8: New Downtube Packings made of Viton / Teflon for Longer Operating Life.

9. Maximum Air Pressure: 150PSI; Recommended Operating Air Pressure 80 - 100PSI; Max Grease Pressure: 7500 PSI; Recommended: 5000 PSI; Note: Pump life reduces considerable if operating above the recommended air pressure.

10: Additional Accessories Available: LT82103ME Grease Strainer for Pump Tube;

11: One Year Limited Warranty against Defective Materials, Workmanship and Labor

12: All Pumps are Pressure Tested Statically and Dynamically at the factory in NLGI #2 Grease for Output, Pressure, Performance and Quality.

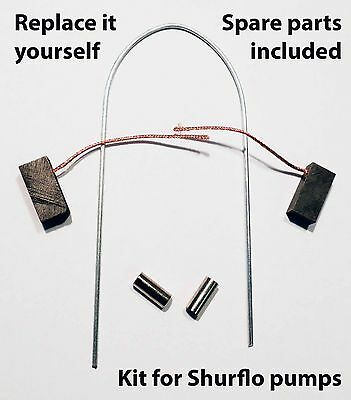

14. Complete Repair Kits Available(See Below).

R83054M: Simple Repair Kit for Grease Pumps LT82513ME

R83054ME: Complete Repair Kit for Grease Pump LT83513ME

R83000ME: Air Motor Repair Kit for LT82513ME

R83001ME: Down Tube Repair Kit for LT82513ME

15: Other Information: Weight and Dimensions:

BOX Weight: 18LBS(8.6KG)

BOX Dimensions: Length: 6-1/2"(16.51CM) X Width:6-1/2" (16.51CM) X Height: 28"(71.12CM)